Scott Block is preserving a way of farm life that used to be common in his area of Illinois. He's raising grain to feed to his cows, and then selling beef as a way to add value to his grain harvest. “I don't farm enough to just live off of grain farming, so I guess I'm trying to do it the way people used to,” he explained. “You got some cattle, you have a little grain farm.” But Block has scaled this business model to modern systems of food production, farming on a much larger scale than his for-bearers. His “little” grain farm includes some 500 acres of his own cropland, and he farms another 1,200 acres that he rents 45 miles away from his main farm. His beef cattle herd is 640 head and he also has a 200-head cow and calf herd. Composting is helping him keep his business model profitable, by helping him solve several of the challenges his large operation faces. It has also provided a new source of revenue for his farm.

Scott Block is preserving a way of farm life that used to be common in his area of Illinois. He's raising grain to feed to his cows, and then selling beef as a way to add value to his grain harvest. “I don't farm enough to just live off of grain farming, so I guess I'm trying to do it the way people used to,” he explained. “You got some cattle, you have a little grain farm.” But Block has scaled this business model to modern systems of food production, farming on a much larger scale than his for-bearers. His “little” grain farm includes some 500 acres of his own cropland, and he farms another 1,200 acres that he rents 45 miles away from his main farm. His beef cattle herd is 640 head and he also has a 200-head cow and calf herd. Composting is helping him keep his business model profitable, by helping him solve several of the challenges his large operation faces. It has also provided a new source of revenue for his farm.“Feeding cattle and hauling manure”

Several years ago, before Block began composting, he built several hoop barns to expand his feedlot to 640 beef cattle. This created a manure problem. “I mean I knew there would a lot of manure when I built the barns. I was originally just going to spread it on my farms here,” he said. But then Block realized just how much manure his larger herd would generate, too much for the 500 acres that he farms close to his feedlot. “I was just feeding cattle, and hauling as much manure as I could, and piling it up quite a bit. Because, of course, there's certain times of the year you can't haul it because of the weather, or what have you.”

Scott's feedlot waste was piling up, and it wasn't economical for him to haul his “raw product” 45 miles away from his main farm where he farms 1,200 acres of grain crops. “The reason I wanted to start composting is because where I grain farm is about a 45 mile drive from where my cattle feedlot is,” Scott said. “I didn't want to haul the raw manure there. (But) I was looking for way to utilize it in order to help the ground,” he explained. “I guess I just probably googled 'composting' or something like that. (That's) how everybody kind of gets started in things it seems like anymore!” he laughed.

Block was also attracted to composting because it would allow him to enhance the fertilizer value of his feedlot waste and reduce his transportation costs so that he could get as much compost onto his cropland as possible, to slowly decrease his dependence on commercial fertilizers. “We've raised cattle our whole lives and we knew where we spread manure you always had better crops. There are still fields where you knew you spread manure on 20 acres right behind the house every winter for 20 years and it probably still raises better crops. I guess the reason I was sold on composting is we were going to have to put less out there to get the same or better results.”The Midwest Bio Systems approach.

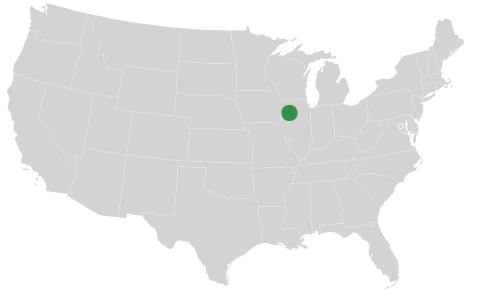

Scott knew he needed an efficient pull-type compost turnerto process all his feed lot waste, as well as a machine that was scaled to the size of his operation. He explained that this is what attracted him to Midwest as he researched turners online. “There were several ways to look at it (composting),” he said. “I guess the way that Edwin (Blosser) and Midwest Bio Systems was doing it was the way I wanted to look at it.” He decided that he should attend a Midwest Bio System's training seminar in Tampico, IL. “So I signed up for one of his (Edwin Blosser's) workshops, I was impressed with everything, I guess it's kind of how I've started.”

Composting is the process of using soil microorganisms to break down organic matter, such as manure or crop residue, into a rich soil amendment. Farmers have created compost for thousands of years, but modern technology and knowledge about the composting process is helping farmers create compost faster, and of much higher quality, than ever before. Midwest Bio System's Advanced Composting System uses this cutting-edge knowledge and technology to help farmers get the results they need quickly and efficiently. It's this efficiency that attracted Scott to the Midwest's composting system.

Before Scott attended the class in the spring of 2011, he was still not entirely sure he was going to start composting on his feedlot. But his experience at the class made him decide to give it a try. “I was impressed with the people. The whole time I was at the workshop they weren't begging me to do this. They were just giving you information. They had some people with experience doing it there. And the people helping them I just kind of liked, and it just looked like the way to go.”

Scott purchased an Aeromaster pull-type compost turner, which arrived on his farm in August 2011. By November of that year he had created 2,000 tons of finished high quality compost and processed all of his feedlot waste. “I had easily 4,000 tons of raw product before I made the compost,” he said. “So I guess I cut my trucking or freight bill in half, you could say. And it wouldn't have had the value of the compost anyway, so I would have had to haul twice as much stuff to get the same, or probably not even the same, amount of results,” he added, pleased with the enhanced fertilizer effect of his finished high quality compost.

And Scott's compost was definitely high quality. It tested at 25 pounds of nitrogen, and 38 pounds of calcium per ton, “which would be the lime for your soil,” he explained. He has begun to completely replace his commercial fertilizer with one ton to the acre of compost on several of his fields, still adding supplemental nitrogen for row support on his corn crop. Scott admits that this transition might be “a little fast,” but he's anxious to become independent from external inputs.

As soon as Block began spreading his compost, his neighbors took notice. When they saw it, they wanted some, he said. News of his compost “spread by word of mouth,” and within a year selling compost is poised to become a huge income-generating element of his farm. Scott even jokes about putting up more barns so he can have more cows just to have more compost-able manure.

The challenges that face farmers today are many, but by using old knowledge, composting, updated to match farming needs in the 21st century, Scott Block is able to keep his traditional business model profitable. Read more in the next post about how compost sales are becoming a new income stream for Scott's business.

How much manure do you have to deal with on a yearly or monthly basis? What strategies are you currently using to deal with this waste?