If the bristles on your toothbrush are worn and bent, how successfully will they create clean, white teeth? If the tines on your compost turner are worn and bent, how successfully will they remove the bad stuff in a compost windrow, namely CO2. Since we all know a good toothbrush promotes good oral health, similarly, good turner tines, promote good, high quality compost.

Tines get the bad stuff out!

It’s critical for the health of the windrow that you practice good CO2 management, replacing the carbon dioxide that builds up there with oxygen. This is accomplished by the design, placement, and durability of the tines mounted on the turner drum. CO2 is a waste product of those billions of little microbial critters in the pile breaking down organic matter. The gaseous exchange which takes place during a pass of the compost turner should result in 4% or less of CO2 in the windrow right after it is turned. This can be measured with a CO2 kit.

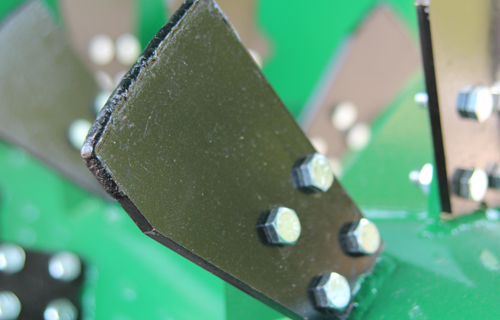

Check tines for wear

Just as we throw out our toothbrush when the bristles get worn down, similarly we must check our tines for wear, and replace them when necessary. The degree of microbial health in the windrow is directly related to the effectiveness of the tines. Worn tines lose their ability to turn the pile as efficiently and effectively. They also increase the power requirement to move the compost turner through the windrow, which increases wear on the drive train, both of which increase your operating costs.

Replace or Repair

When tines become worn more than 3/8 inch, they should be replaced using new bolts and locknuts. If your tines aren’t completely worn, you may be able to get a little more life out of them by turning them around and installing them on the opposite end of the drum using new hardware. Just make sure the tines aren’t worn more than 3/8 inch.

We’ve put a lot of time and effort into producing a very high-quality drum-and-tines combination. Abrasion-resistant hard-faced steel tines reduce wear and extend tine life. Aeromaster tines come with a hard faced bead welded on the tip. Maintaining this bead can triple the life of the tine. All this requires is a trip to a welding shop to have the bead reapplied, or you can do it yourself if you have welding capabilities.

Is now the right time?

If you want high quality compost, you’ve got to keep out the bad stuff and promote the life of the good stuff. It may seem trivial, but the tines on the drum of the turner will help you do just that! Replace worn tines when it’s time to do so. After you install new ones, operate your compost turner to check for dynamic balance of the drum-and-tines partnership.

Is it time for you to check your tines? Do you think worn tines could be increasing the cost of your operation and/or lowering the quality of your end-product? Do you have any other questions about tines? If so, post them in the comments.